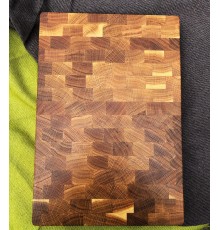

An end grain cutting board is a board in which the wood grain runs perpendicular to the cutting surface, rather than parallel as in regular cutting boards.

Most professional chefs use end-grain cutting boards. Explanations: 1. The end grain of wood is stronger and more durable. The hardness of the end grain of wood is almost one and a half times greater than the side grain. 2. When using an end grain cutting board, knives stay sharper longer and require less frequent sharpening. This makes a big difference when knives are sharpened several times a day. 3. It is clear that with repeated cuts, the fibers are cut in several places, and microscopic particles of wood end up in food. An end grain cutting board is less susceptible to bacterial contamination, since the fibers are "locked" after cutting, and the oil coating protects against the penetration of bacteria into the fibers. href="https://mtmwood.com/index.php?route=information/information&information_id=10">hygienic than plastic or glass cutting boards.

· The board must be lubricated with mineral oil and water, and it cannot be washed in the dishwasher at the same time.

· It is not recommended to cover hot (steaming) dishes with a board

Please note that following these recommendations will significantly increase the lifespan of your end grain cutting boards, resulting in even greater enjoyment!

Dimensions: 280*205*40 mm

Treated with linseed oil based on beeswax.

Characteristics

There are no reviews for this product.

No questions about this product.